Energy efficiency

As part of our energy efficiency business line, we offer solutions that help reduce resource consumption, both in green hydrogen projects and in stand-alone initiatives in industry, logistics and infrastructure.

We highlight five main blocks of technologies that improve energy efficiency

Heat utilisation through heat pumps

Technology 1

Excess heat generated in industrial processes can be reused to:

reduce energy consumption

improve plant efficiency

reduce carbon footprints

Recovering excess heat is a proven way to reduce energy waste and enhance the sustainability of industrial processes.

Heat pumps harmoniously complement electrolysis plants for the production of green hydrogen in order to increase the potential and commercialisation of thermal energy.

Absorption chillers work by utilising excess heat to solve cooling problems, which is particularly relevant in industries with a high demand for air conditioning or low-temperature storage.

These technologies help to reduce CO₂ emissions and lower conventional energy costs.

Pairing an absorption chiller with CHP can provide additional medium-capacity cooling from green hydrogen projects for sale to local customers.

Solar power plants and energy storage

Technology 2

Solar power plants enable the generation of clean electricity, reducing dependence on fossil fuels and conventional energy systems.

Modern photovoltaic panels offer high efficiency in converting sunlight into electricity and can be used in both stand-alone and grid-connected solutions.

Energy storage devices (batteries) allow excess electricity to be stored, ensuring uninterrupted power supply at night or during peak loads.

This is particularly relevant for industrial facilities, commercial buildings and data centres where the stability of the power supply is critical.

Energy storage enables the creation of decentralised islanded microgrids, as well as the ability to provide ancillary services to the grid for frequency regulation and daily load balancing.

Wastewater treatment and water treatment

Technology 3

Water treatment plays an important role in industry, providing the necessary water quality for:

reverse osmosis

boiler plants

cooling systems

drinking water supply

Modern water treatment systems include reverse osmosis, ultrafiltration, ion exchange technology and biological treatment to remove pollutants, salts, heavy metals and organic impurities.

The reuse of treated water helps companies to significantly reduce freshwater consumption, lower water supply costs and reduce their environmental footprint.

The MBR membrane bioreactor technology, thanks to its remote ultrafiltration modules, enables the realisation of ultra-compact wastewater treatment plants, while performing a deep treatment of wastewater that can be released directly into water bodies after treatment or reused.

The use of oxygen by-product from electrolysis projects to supply the treatment plants helps increase the efficiency of wastewater treatment technology and at the same time to create conditions for additional commercial effect for green hydrogen production projects.

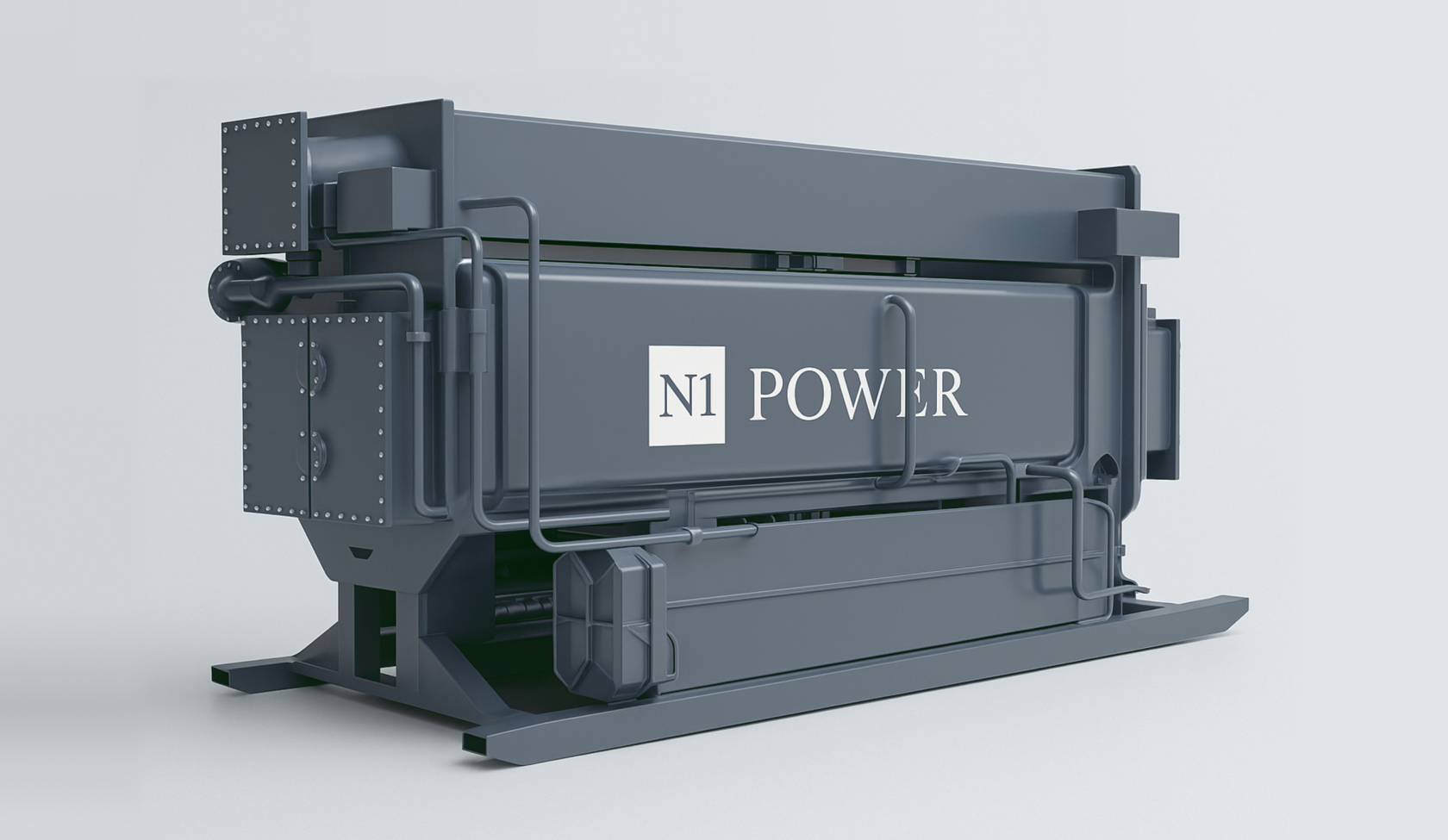

Gas piston units

Technology 4

Gas piston plants are a reliable and flexible source of electricity and heat generation, able to run on natural gas, biogas and hydrogen.

They ensure the energy independence of enterprises by allowing the generation of electricity and heat directly on site, which reduces the load on centralised networks and reduces energy costs.

An additional advantage is the possibility of using these units in cogeneration and trigeneration systems, when up to three types of energy carriers are produced in one technological cycle:

electricity

heat

cold

The units operate on various organic gas fuels, such as natural gas, propane, associated petroleum gas, and can also use renewable and regenerated gases: biogas from sewage treatment plants and various animal and vegetable wastes, landfill gas from solid municipal waste landfills, mine methane, process gases from metallurgical furnaces and gasification processes.

Modern plants can use green hydrogen as fuel for local production of electricity and heat with zero carbon footprint. Cogeneration gas piston plants that are operated on natural gas can be converted to green hydrogen in the future as part of a modernisation programme, thus avoiding future frozen assets.

Due to their flexibility and mobility, the plants play the role of balancing efficient energy sources with a low carbon footprint.

Projects can be realised in batches thanks to the cluster configuration. The equipment is housed in open machine rooms as well as in outdoor containers.

When paired with photovoltaic power plants and storage systems, gas piston plants enable the implementation of hybrid energy source projects that combine the functional advantages of both systems.

Automation, digitalisation solutions

Technology 5

The company offers solutions in the field of process automation, sensors, gauges, measurement systems, asset monitoring, data storage and analysis, flexible algorithms, SCADA systems.

Applications for data collection, monitoring and asset management with elements of artificial intelligence and neural networks allow companies to increase the efficiency of service maintenance, extend the life cycle of equipment, and reduce accidents through predictive analytics.

We also offer to digitalise the process of construction and operation of facilities using BIM 4/5/6/7D technologies. During the design process, a digital BIM model with LOD-400 level of detail will be developed, which will be the basis for the digitalisation of subsequent processes.

Energy service contracts and energy audit

Approach

We are ready to offer customers not just equipment, but financing and operating tools, in particular, a ready-made energy service contract (ESCO) model.

This approach is particularly favourable for businesses: we conduct an audit, identify savings points and implement the necessary systems, and then the customer pays for the implementation from the savings.

We accompany the project at all stages to make the implementation of energy efficient solutions convenient and profitable.

We are responsible for turnkey construction of the project, organisation of all necessary permits, financing of capital expenditures, operation of the asset during the warranty and post-warranty period. We finance and operate projects of various configurations:

Power as a Service

Heat as a Service

Energy efficiency as a Service

Find Your Optimal Energy Solution

Download the questionnaire for your primary energy goal, fill it out, and send it to info@n1-power.com. We’ll prepare a personalized offer for you.